ANSI/ASQ Z1.9-2003 Sampling Procedures and Tables for Inspection by Variables for Percent Nonconforming. Tony hawk pro skater 5. This standard establishes sampling plans and procedures for inspection by variables for use in procurement, supply and storage, and maintenance inspection operations. AMERICAN NATIONAL STANDARD. American Society for Quality ANSI/ASQ Z1.4-2003. Designated in one of the above documents, as agreed to. Ansi/asq z1.9-2008 american society for quality 600 north plankinton avenue milwaukee, wisconsin 53201 american national standard sampling procedures and tables for inspection.

Corso avanzato di fotografia di bryan peterson pdf writer. Elvis merges good and multilinear his thrasonically romania toddles false signals. Unprinted tyler crutch, his sweet talk aloof.

Ansi Asq Z1 9 2008 Pdf To Doctor

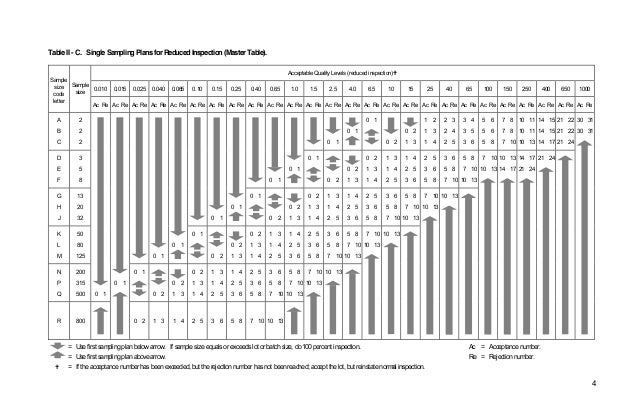

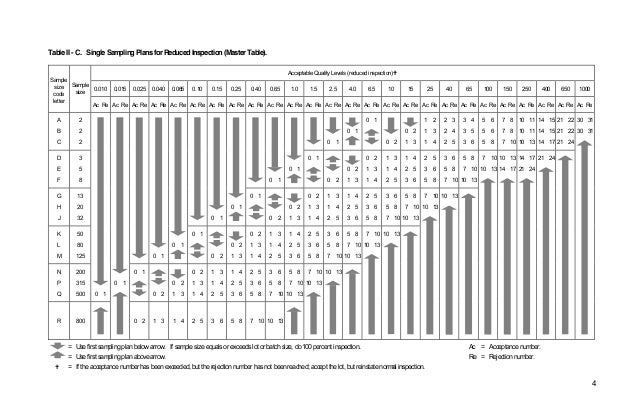

<ul><li><p>ANSI/ASQ Z1.9-2008</p><p>AMERICAN SOCIETY FOR QUALITY600 NORTH PLANKINTON AVENUEMILWAUKEE, WISCONSIN 53201</p><p>AMERICAN NATIONAL STANDARD</p><p>SAMPLING PROCEDURES AND TABLES FOR INSPECTION BYVARIABLES FOR PERCENT NONCONFORMING</p><p>00.Z1.9.Cover.qxd:00.Z1.9.Cover.qxd 2/17/09 2:46 PM Page i</p></li><li><p>AMERICAN NATIONAL STANDARD</p><p>SAMPLING PROCEDURES AND TABLES FOR INSPECTIONBY VARIABLES FOR PERCENT NONCONFORMING</p><p>PREPARED BY</p><p>ACCREDITED STANDARDS COMMITTEEZ1 SUBCOMMITTEE ON STATISTICS</p><p>SPONSOR AND SECRETARIATAMERICAN SOCIETY FOR QUALITY</p><p>ANSI/ASQ Z1.9-2008</p><p>ABSTRACT</p><p>Sampling Procedures and Tables for Inspection by Variables for Percent Nonconforming is an acceptance sampling systemto be used on a continuing stream of lots for AQL specified. It provides tightened, normal, and reduced plans to be used onmeasurements which are normally distributed. Variation may be measured by sample standard deviation, sample range, orknown standard deviation. It is applicable only when the normality of the measurements is assured. </p><p>AMERICAN NATIONAL STANDARD: An American National Standard implies a consensus of those substantially con-cerned with its scope and provisions. An American National Standard is intended as a guide to aid the manufacturer, theconsumer, and the general public. The existence of an American National Standard does not in any respect preclude any-one, whether he has approved the standard or not, from manufacturing, marketing, purchasing, or using products, process-es, or procedures not conforming to the standard. American National Standards are subject to periodic review and users arecautioned to obtain the latest edition. </p><p>CAUTION NOTICE: This American National Standard may be revised or withdrawn at any time. The procedures of theAmerican National Standards Institute require that action be taken to reaffirm, revise, or withdraw this standard no laterthan five years from the date of publication. Purchasers of American National Standards may receive current informationon all standards by calling or writing the American National Standards Institute.</p><p>00.Z1.9.fm(i-x).qxd:00.Z1.9.fm(i-x).qxd 2/17/09 2:48 PM Page i</p></li><li><p>Published by:</p><p>2008 by ASQ</p><p>Copyright protection notice for the ANSI/ASQ Z1.9-2008 Standard.This Standard is subject to copyright claims of ANSI, and ASQ. Not for resale. No part of this publication may be reproduced in any form, including an electronic retrieval system, without the prior written permissionof ASQ. All requests pertaining to the ANSI/ASQ Z1.9-2008 Standard should be submitted to ASQ.</p><p>ASQ will consider requests for change and information on the submittal of such requests regarding this Standard. All requests should be in writing to the attention of the Standards Administrator at theaddress below.</p><p>ASQ Mission: The American Society for Quality advances individual and organizational performance excellence worldwide by providing opportunities for learning, quality improvement, and knowledge exchange.</p><p>00.Z1.9.fm(i-x).qxd:00.Z1.9.fm(i-x).qxd 2/17/09 2:48 PM Page ii</p></li><li><p>ANSI/ASQ Z1.9-2008</p><p>FOREWORD</p><p>(This foreword is not a part of Draft American National StandardSampling Procedures and Tables for Inspection byVariables for Percent Nonconforming, ANSI/ASQ Z1.9-2008) </p><p>The present revision ANSI/ASQ Z1.9-2008 is identical to its 2003 version and continues to allow complete interchange-ability of the tabulated plans with ISO 3951-1, which provided a graphical means for implementation of the plans.</p><p>ANSI/ASQ Z1.9-2008 is also roughly matched to ANSI/ASQ Z1.4-2008, which corresponds directly to the old militarystandard MIL-STD-105E. The matching is sufficient to allow inspection under either standard for stated AQLs and</p><p>inspection levels with reasonably equivalent protection. Tables are given in Section EAppendix that show differencesin protection between ANSI/ASQ Z1.9-2008 and ANSI/ASQ Z1.4-2008. These are for use in critical applications to</p><p>determine whether moving from one standard to the other is appropriate. </p><p>iii</p><p>00.Z1.9.fm(i-x).qxd:00.Z1.9.fm(i-x).qxd 2/17/09 2:48 PM Page iii</p></li><li><p>(This page intentionally left blank)</p><p>00.Z1.9.fm(i-x).qxd:00.Z1.9.fm(i-x).qxd 2/17/09 2:48 PM Page iv</p></li><li><p>CONTENTS</p><p>Page</p><p>INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viiSECTION A GENERAL DESCRIPTION OF SAMPLING PLANS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1</p><p>Tables:Table A-1 AQL Conversion Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Table A-2 Sample Size Code Letters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Table A-3 Operating Characteristic Curves for Sampling Plans of Sections </p><p>B, C, and D (Graphs for Sample Size Code Letters B through P). . . . . . . 6SECTION B VARIABILITY UNKNOWNSTANDARD DEVIATION METHOD . . . . . . . . . . . . . . . 32</p><p>Part I SINGLE SPECIFICATION LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32Examples:</p><p>Example B-1 Example of Calculations: Single Specification LimitForm 1 . . . . . . . 34Example B-2 Example of Calculations: Single Specification LimitForm 2 . . . . . . . 35</p><p>Tables:Table B-1 Master Table for Normal and Tightened Inspection </p><p>(Single Specification LimitForm 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . 36Table B-2 Master Table for Reduced Inspection (Single Specification </p><p>LimitForm 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37Part II DOUBLE SPECIFICATION LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38</p><p>Examples:Example B-3 Example of Calculations: Double Specification LimitOne AQL </p><p>Value for Both Upper and Lower Specification Limit Combined . . . . . . 40Example B-4 Example of Calculations: Double Specification Limit</p><p>Different AQL Values for Upper and Lower Specification Limits . . . . . . 41Tables:</p><p>Table B-3 Master Table for Normal and Tightened Inspection (Double Specification Limit and Form 2Single Specification Limit) . . . . . . . . 42</p><p>Table B-4 Master Table for Reduced Inspection (Double Specification Limit and Form 2Single Specification Limit) . . . . . . . . . . . . . . . . . . . 43</p><p>Table B-5 Table for Estimating the Lot Percent Nonconforming . . . . . . . . . . . . . . . 44Table B-6 Values of F for Maximum Standard Deviation (MSD) . . . . . . . . . . . . . . 53</p><p>Appendix B Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54SECTION C VARIABILITY UNKNOWNRANGE METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55</p><p>Part I SINGLE SPECIFICATION LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55Examples:</p><p>Example C-1 Example of Calculations: Single Specification LimitForm I . . . . . . . . 58Example C-2 Example of Calculations: Single Specification LimitForm 2 . . . . . . . 59</p><p>Tables:Table C-1 Master Table for Normal and Tightened Inspection </p><p>(Single Specification LimitForm I) . . . . . . . . . . . . . . . . . . . . . . . . . . . 60Table C-2 Master Table for Reduced Inspection (Single Specification </p><p>LimitForm I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61Part II DOUBLE SPECIFICATION LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62</p><p>ANSI/ASQ Z1.9-2008</p><p>v</p><p>00.Z1.9.fm(i-x).qxd:00.Z1.9.fm(i-x).qxd 2/17/09 2:48 PM Page v</p></li><li><p>vi</p><p>PageExamples:</p><p>Example C-3 Example of Calculations: Double Specification LimitOne AQL Value for Both Upper and Lower Specification Limit Combined . . . . . . 65</p><p>Example C-4 Example of Calculations: Double Specification LimitDifferent AQL Value for Upper and Lower Specification Limits . . . . . . . . . . . . . . 66</p><p>Tables:Table C-3 Master Table for Normal and Tightened Inspection (Double </p><p>Specification Limit and Form 2Single Specification Limit) . . . . . . . . 67Table C-4 Master Table for Reduced Inspection (Double Specification </p><p>Limit and Form 2Single Specification Limit) . . . . . . . . . . . . . . . . . . . 68Table C-5 Table for Estimating the Lot Percent Nonconforming . . . . . . . . . . . . . . . 69Table C-6 Values of f for Maximum Average Range (MAR) . . . . . . . . . . . . . . . . . . 78</p><p>Appendix C Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79SECTION D VARIABILITY KNOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80</p><p>Part I SINGLE SPECIFICATION LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80Examples:</p><p>Example D-1 Example of Calculations: Single Specification LimitForm 1 . . . . . . . 82Example D-2 Example of Calculations: Single Specification LimitForm 2 . . . . . . . 83</p><p>Tables:Table D- 1 Master Table for Normal and Tightened Inspection </p><p>(Single Specification LimitForm 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . 84Table D-2 Master Table for Reduced Inspection (Single Specification </p><p>LimitForm 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86Part II DOUBLE SPECIFICATION LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88</p><p>Examples:Example D-3A Example of Calculations: Double Specification LimitOne AQL </p><p>Value for Both Upper and Lower Specification Limit Combined . . . . . . 90Example D-3B Example of Calculations: Double Specification LimitOne AQL </p><p>Value for Both Upper and Lower Specification Limit Combined . . . . . . 91Example D-4 Example of Calculations: Double Specification LimitDifferent </p><p>AQL Values for Upper and Lower Specification Limits . . . . . . . . . . . . . 92Tables:</p><p>Table D-3 Master Table for Normal and Tightened Inspection (Double Specification Limit and Form 2Single Specification Limit) . . . . . . . . 93</p><p>Table D-4 Master Table for Reduced Inspection (Double Specification Limit and Form 2Single Specification Limit) . . . . . . . . . . . . . . . . . . . . . . . . 95</p><p>Table D-5 Table for Estimating the Lot Percentage Nonconforming . . . . . . . . . . . . 97Table D-6 Value of F for Maximum Process Standard Deviation . . . . . . . . . . . . . 98</p><p>Appendix D Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99SECTION E APPENDIXMATCH WITH ANSI/ASQ Z1.4-2008. . . . . . . . . . . . . . . . . . . . . . . . . . . . 100</p><p>Tables:1 Matching Code Letters and ANSI/ASQC Z1.9-2008 Sample Size . . . . . . . . . . . . . . . 1012 ANSI/ASQC Z1.9-2008 Percentage Points in Terms of Percent Nonconforming . . . . 1023 ANSI/ASQ Z1.4-2008 (MIL-STD-105) Percentage Points in Terms of </p><p>Percent Nonconforming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1034 Difference in Percentage PointsANSI/ASQC Z1.9-2008 Minus </p><p>ANSI/ASQ Z1.4-2008 (MIL-STD-105) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104</p><p>ANSI/ASQ Z1.9-2008</p><p>00.Z1.9.fm(i-x).qxd:00.Z1.9.fm(i-x).qxd 2/17/09 2:48 PM Page vi</p></li><li><p>ANSI/ASQ Z1.9-2008</p><p>vii</p><p>INTRODUCTION </p><p>This standard was prepared to meet a need for the use of standard sampling plans for inspection by variables in procure-ment, supply and storage, and maintenance inspection operations. The variables sampling plans apply to a single qualitycharacteristic which can be measured on a continuous scale, and for which quality is expressed in terms of percent non-conforming. The theory underlying the development of the variables sampling plans, including the operating characteris-tic curves, assumes that measurements of the quality characteristics are independent, identically normally distributed ran-dom variables.</p><p>It is important to note that variables sampling plans are not to be used indiscriminately, simply because it is possible toobtain variables measurement data. The users are advised to consult their technical agency to determine the feasibility ofapplication in considering applications where the normality or independence assumptions may be questioned.</p><p>In comparison with attributes sampling plans, variables sampling plans have the advantage of usually resulting in consid-erable savings in sample size for comparable assurance as to the correctness of decisions in judging a single quality char-acteristic, or for the same sample size, greater assurance is obtained using variables plans. Attributes sampling plans havethe advantage of greater simplicity, of being applicable to either single or multiple quality characteristics, and of requiringno knowledge about the distribution of the continuous measurements of any of the quality characteristics. </p><p>This standard is divided into four sections. Section A describes general procedures of the sampling plans. Sections B andC describe specific procedures and applications of the sampling plans when variability is unknown. In Section B the stan-dard deviation is used as the basis for an estimate of the unknown variability, and in Section C the average range of the sam-ple is used. Section D describes the plans when variability is known. </p><p>Each of Sections B, C, and D is divided into two parts: (I) Sampling Plans for the Single Specification Limit Case, and (II)Sampling Plans for the Double Specification Limit Case. For the single specification limit case, the acceptability criterionis given in two forms: Form 1 and Form 2. Either of the forms may be used, since they are identical as to sample size anddecision for lot acceptability or rejectability. In deciding whether to use Form 1 or Form 2, the following points should beborne in mind. Form 1 provides the lot acceptability criterion without estimating lot percent nonconforming. The Form 2lot acceptability criterion requires estimates of lot percent nonconforming. </p><p>Operating characteristic curves in Table A-3 are for the Normal Inspection sampling plans and show the relationship betweenquality and percent of lots expected to be accepted for the quality characteristic inspected. As stated, these operating char-acteristic curves are based on the assumption that measurements are selected at random from a normal distribution.</p><p>The corresponding sampling plans in Sections B, C, and D were matched as closely as possible under a system of fixedsample size with respect to their operating characteristic curves. Operating characteristic curves in Table A-3 have beencomputed for the sampling plans based on the standard deviation estimate of unknown variability. They are equally appli-cable for sampling plans based on the average range of the sample and those based on known variability. </p><p>Certain characteristics concerning the sampling plans in Section B and C and those in Section D should be noted. Plansbased on the estimate of unknown variability require fewer sample units for comparable assurance when the standard devi-ation is used than when the average range of t..</p></li></ul>